|

|

SMCLM-10B-AT Automatic Card Laminator

SMCLM-10B-AT Automatic Loading & Transfer RFID Dual-Interface Smart Card Laminator is automatic load trays with materials upto each daylight, automatic transfer trays with materials from hot tower to cold tower, the automatic functions are specially made because of big size materials with trays with plates will be over 60KGS for A2 size, but now even a young girl without strong power can operate machine well.

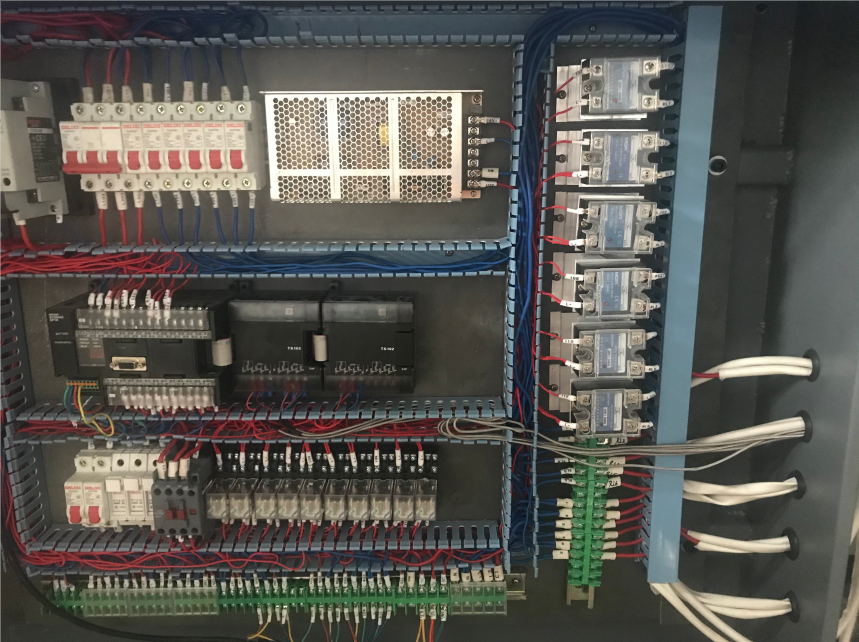

Operation Panel Automatic Load Trays Omron PLC and Temperature Modules Operation Steps: 1.Just for the first time , two operators need to take tray with materials into the loader. 2.Choose the setting by touch-screen to automatic move up tray with materials to each daylight by servo system. 3.Push trays into hot lamination tower and press "start hot lamination" switch. 4.After hot lamination , hot lamination daylights automatic open and press "transfer" switch, automatic transfer trays from hot lamination daylights to cold lamination daylights, and the automatic transfer module automatic back to origin position. 5.Press "start cold lamination" switch for cold lamination. 6.At the same time laminate another 10 trays for hot lamination. 7. When cold lamination finish, operator take each tray out from cold lamination daylights and get laminated sheets, at the same time put new materials into trays on the loader, no need to take out plates and pad, save time and save labour, no need strong man to do this job. Configurations: 1. Separate two softwares: one software to control trays automatic loading up and down to all lamination daylights, another software to control hot daylights lamination and cold daylights lamination with time & pressure & temperature setting. |